When a major auto parts supplier discovered 57% of their production delays came not from laser cutters, but from manual part sorting, they turned to QHMAG’s electro-permanent magnetic lifter. Within weeks:

Unloading time dropped from 60 mins → 90 seconds

Energy bills plunged $120,000/year

Worker injuries near machinery fell to zero

This is the reality for 300+ factories who ditched outdated lifting gear. Let’s dissect why.

Traditional material handling drains profit through:

Electromagnets: Guzzle power 24/7 ($15-40/hour in electricity)

Manual Sorting: 3-4 workers wasted on post-cut part retrieval

Unplanned Downtime: Load drops cost $8k/minute in auto plants (Ford internal data)

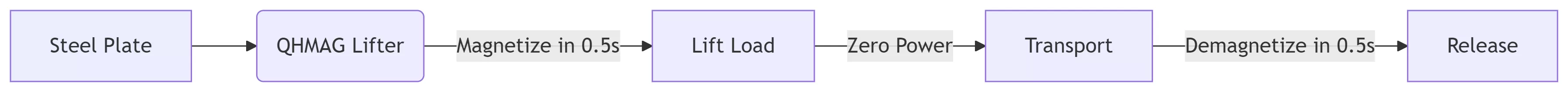

QHMAG’s solution? Electro-permanent magnets that work without continuous power.

3-Second Power Bursts: Only consumes electricity during magnetization/demagnetization.

Power-Outage Proof: Holds loads indefinitely during blackouts

Full-Coverage Grip: Lifts 200-500 laser-cut fragments in one pass.

| Metric | Before QHMAG | After QHMAG |

|---|---|---|

| Unloading Time | 60 min | 90 sec |

| Energy Cost | $142,000/yr | $7,100/yr |

| Labor Per Shift | 4 workers | 0 workers |

Foundries: Handle 600°C steel billets with <2% magnetic decay

Aerospace: Transfer wing skins with zero micro-scratches

Medical Device Mfg: ISO Class 5 cleanroom-compatible models

“We recouped costs in 5 months. Now even our forklift drivers operate the lifter via remote.”

— Engineering Manager, Siemens Aerospace

Calculate savings with 3 variables:

Current unloading time: _____ mins/batch

Labor cost/hour: _____ $

Electromagnet energy use: _____ kW/h

→ Free ROI Calculator Tool:QHMAG

Certified Safety: CE, ISO 9001, OSHA compliant

Smart Integration: IoT-enabled force adjustment + predictive maintenance

Global Support: 24/7 engineers in 12 time zones

While competitors sell hardware, QHMAG delivers:

✅ 10-20x faster unloading

✅ 95% energy reduction

✅ 100% drop-free operations

Your move: Stick with profit-draining methods, or join the 300+ factories who upgraded.

Connect with our engineers on WhatsApp for a custom solution:+86 18974071177

Facebook:QHMAG

Official website:www.qhmagnet.com

Attn: Ian Yi

Mob: 8618974071177 (Wechat/ WhatsApp)

Email: [email protected]

Address: 101 room, 16 Building, LIANDO U VALLEY, No.36 Zhongke Road, Economic and Technological Development Zone, Yueyang City, Hunan Province, China