In the rapid development of manufacturing industry today, injection molding machine as an important production equipment, its mold change efficiency directly affects the overall operation of the production line. The traditional mode change has the problems of complicated operation and low efficiency, and the emergence of magnetic platen of injection molding machine provides an effective solution for these problems.

magnetic platen uses the strong magnetic force to firmly adsorb the mold on the injection molding machine, realizing the rapid and safe mold replacement. Compared with the traditional mechanical locking method, the magnetic platen does not need the complex bolt tightening process, which greatly reduces the mold change time. At the same time, its operation is simple, reduce the labor intensity of workers, improve the work efficiency.

In addition, the magnetic platen also has the characteristics of compact structure, small space occupied, which makes the overall layout of the injection molding machine more reasonable. This is not only conducive to equipment maintenance and maintenance, but also improves the flexibility of the production line. More importantly, the introduction of magnetic platens also has a positive impact on the stability and safety of the production line.

In practice, the magnetic force template shows its excellent performance. First, the strong magnetic force of the magnetic platen ensures the stability of the mold in high-speed operation and reduces the risk of mold shedding or displacement. This helps to reduce unexpected downtime during production and improve productivity.

Secondly, the automatic control system of the magnetic force template can monitor the state of the mold in real time and automatically release the magnetic force when the mold needs to be replaced. This not only improves the automation level of mode change, but also reduces the influence of human factors on the mode change process and reduces the risk of operation errors.

In addition, the magnetic force template also has the function of data acquisition and transmission. By collecting and analyzing the data in the process of mold replacement, the enterprise can more accurately grasp the operation status of the production line, optimize the production process, and further improve the production efficiency and quality.

magnetic platens also play an important role in environmental protection and energy saving. Because the introduction of magnetic platens reduces the energy consumption and waste discharge required for mechanical locking, it helps enterprises to achieve green production and sustainable development.

In short, the magnetic platen of an injection molding machine, as an innovative solution, has shown significant advantages in improving the efficiency of mold change, optimizing the production process, and ensuring the production safety. With the continuous progress of technology and the continuous promotion of application, it is believed that the magnetic platen will play a more important role in the future manufacturing industry.

-----------------------------------------------------------------------------------

Analysis of the advantages of magnetic force template in the application of injection molding machine

As an innovative mold fixing device, the magnetic platen of injection molding machine shows many advantages in the application of injection molding machine. In our previous analysis, we have mentioned significant features in terms of safety, stability, and economic benefits. Next, we will further explore the specific manifestation of these advantages.

First of all, from the perspective of safety, the magnetic platen will firmly adsorb the mold on the injection molding machine through the strong magnetic force, to ensure that the mold will not fall off due to bolt loosening or fracture at high speed. This design not only eliminates the potential risk of mold loss, but also reduces the equipment damage and personnel damage that may be caused by the mold loss, thus greatly improving the safety of production.

Secondly, the magnetic force template also has significant advantages in terms of stability. Because the magnetic platen has stable magnetic performance, it can ensure that the mold remains stable at high speed and reduce the vibration and displacement of the mold. This not only helps to reduce the wear and failure rate of the mold, prolong the service life of the mold, but also improves the quality and consistency of the product. In addition, the strong magnetic force of the magnetic platen can be evenly distributed throughout the surface of the mold, thus preventing the local stress of the mold and further improving the stability of the mold.

Finally, from the point of view of economic benefit, the introduction of magnetic platen brings significant economic benefits to the application of injection molding machine. First, the magnetic platen simplifies the fixing process of the mold without the need for complex fastening devices such as bolts, thus greatly shortening the mold change time. This not only improves the production efficiency, but also reduces the labor intensity of the workers and reduces the labor costs. Secondly, the stability and safety of the magnetic platen reduce the failure rate and maintenance cost of the mold, and further reduce the production cost. In addition, the introduction of magnetic platens also helps to improve the quality and consistency of products, thus enhancing the market competitiveness of enterprises.

In conclusion, the magnetic platen of injection molding machine shows significant advantages in terms of safety, stability and economic benefits. These advantages can not only help to improve production efficiency and reduce production costs, but also help to improve product quality and enhance enterprise competitiveness. With the continuous progress of the technology and the continuous promotion of the application, it is believed that the magnetic platen will play a more important role in the future application of the injection molding machine.

-----------------------------------------------------------------------------------

Selection and application of magnetic platen of injection molding machine

When choosing the magnetic platen of the injection molding machine, the careful consideration of various factors is the key to ensure the production efficiency and safety. Next, we will explore how to select the magnetic platen according to the actual requirements, and analyze the precautions in practical application in detail.

1. Selection of the magnetic force template

1. Selection according to the model and specification of the injection molding machine:

First of all, to understand the model and specifications of the injection molding machine, including its maximum opening and closing stroke, template size and other key parameters.

According to these parameters, the corresponding size of the magnetic platen is determined to ensure that the magnetic platen can fully cover the template of the injection molding machine and provide sufficient magnetic adsorption area.

At the same time, attention should be paid to the load-bearing capacity of the magnetic platen to ensure that it can withstand the weight of the mold and the impact force generated during the injection molding process.

2. Consider the weight and size of the mold:

The weight and size of the mold are important reference factors for selecting the magnetic platen model.

Based on the actual weight and size of the mold, a magnetic platen with sufficient magnetic force and adsorption area is selected to ensure that the mold can be stably fixed to the injection molding machine.

For large or heavy duty molds, higher performance magnetic platens may be required to meet production requirements.

2. Precautions in the practical application of magnetic force templates

1. Installation position and fixing method:

When installing the magnetic platen, choose the appropriate position to ensure that the magnetic platen can completely cover the template of the injection molding machine and fit closely with the mold.

When fixing the magnetic platen, use appropriate fixtures and fasteners to ensure the stability and safety of the magnetic platen.

Check the status of fixtures and fasteners regularly, and replace them timely if loose or damaged.

2. Operation and maintenance:

When using magnetic platens, follow the operating procedures to avoid damage or failure of magnetic platens caused by excessive force or improper operation.

Clean and maintain the magnetic formwork regularly to keep the surface clean and dry to avoid corrosion and contamination.

If abnormal conditions such as magnetic weakening or failure are found, investigation and maintenance should be carried out in time to ensure the normal operation of the magnetic platen.

3. Safety protection:

When using magnetic platen, we should pay attention to safety protection measures to avoid the damage caused by magnetic platen to human body or equipment.

If changing the mold or performing other operations, ensure that the magnetic platen is in the closed state to avoid accidents caused by misoperation.

To sum up, the selection and application of the magnetic platen of the injection molding machine need to consider many factors, including the injection molding machine model, mold weight and size. In practical application, attention should be paid to the selection of installation location and fixed mode, the specification of operation and maintenance, and the implementation of safety protection measures. Through reasonable selection and application, we can ensure the best performance of the magnetic platen in the production of injection molding machine, and improve the production efficiency and safety.

-----------------------------------------------------------------------------------

magnetic platen technology helps the injection molding machine intelligent upgrade

With the further development of intelligent manufacturing technology, the injection molding machine industry is ushering in a wave of intelligent upgrading. In this revolution, the magnetic platen technology, with its unique advantages, has become an important force to promote the intelligent upgrade of the injection molding machine.

First of all, the magnetic platen technology makes the injection molding machine mold replacement more rapid and safe. The traditional mold replacement method requires manual operation, which is not only time-consuming and laborious, but also has potential safety risks. The magnetic force template holds the mold firmly on the injection molding machine through the strong magnetic force, which realizes the rapid replacement of the mold. This not only greatly saves time, improves production efficiency, but also reduces the risk of manual operation and ensures production safety.

Secondly, the magnetic platen technology has the function of data collection and transmission, which provides data support for the intelligent upgrade of the injection molding machine. During the operation of the injection molding machine, the magnetic platen can collect the key data of mold replacement time and mold use times in real time, and transmit these data to the control system of the injection molding machine. Through the analysis of these data, the control system can realize the accurate control of the production process, optimize the production parameters, and improve the production efficiency and product quality.

In addition, the magnetic platen technology can also be seamlessly connected with other intelligent systems of the injection molding machine, forming a complete intelligent production system. For example, the magnetic platen can cooperate with the automatic feeding system and quality detection system of the injection molding machine to realize the automation and intelligence of the production process. This can not only further improve production efficiency and reduce production costs, but also improve product quality to meet the market demand for high-quality products.

Finally, the application of magnetic platen technology also helps to promote the green manufacturing and sustainable development of the injection molding machine industry. By optimizing production processes and improving production efficiency and quality, energy consumption and waste emissions can be reduced and the environmental impact can be reduced. At the same time, the introduction of magnetic platen technology can also promote the innovation and development of the injection molding machine industry, and promote the whole industry to be more intelligent, environmental protection direction.

In short, the magnetic platen technology, as an innovative solution, provides a strong support for the intelligent upgrade of the injection molding machine. Through the introduction of magnetic platen technology, injection molding machine can realize rapid and safe mold replacement and improve the automation level of production line; while the data collection and transmission function of magnetic platen can be seamlessly connected with the control system of injection molding machine to realize the real-time monitoring and analysis of production data; in addition, magnetic platen technology can cooperate with other intelligent systems to form a complete intelligent production system; finally, the application of magnetic platen technology also helps to promote the green manufacturing and sustainable development of injection molding machine industry. With the continuous progress of the technology and the continuous deepening of the application, we believe that the magnetic platen technology will play a more important role in the injection molding machine industry.

-----------------------------------------------------------------------------------

Maintenance and maintenance of the magnetic platen of injection molding machine

The netic template is an important part of injection molding machine, and its stable operation is crucial to ensure production efficiency and product quality. In order to ensure that the magnetic platen can run stably for a long time, regular maintenance and maintenance is essential. The following will detail the magnetic platen maintenance and maintenance methods, as well as common faults and solutions.

1. Maintenance method

1. Magnetic force performance check:

Check the magnetic performance of the magnetic platen regularly to ensure that it can absorb the mold stably.

Use the magnetic force measurement instrument to test the magnetic force of the magnetic force template. If the magnetic force is found to weaken, the magnet needs to be adjusted or replaced in time.

2. Check the parts:

Check whether the connection between the magnetic platen and the injection molding machine is fastened and reliable to avoid loosening or falling off when the mold is replaced or running.

Tighten the connections with the appropriate tools to ensure a secure connection.

3. Cleaning and drying:

Keep the magnetic platen clean and dry, without corrosion and contamination.

Wipe the surface of the magnetic platen regularly with a soft cloth to remove dust and grease.

If the magnetic platen surface is found to be rusty or stained, it can be cleaned with an appropriate detergent.

4. Lubrication and maintenance:

For lubricating parts in magnetic formwork, such as sliding track, bearing, lubricating oil or grease should be added regularly.

Select a suitable lubricant to ensure the smooth operation of the magnetic force template.

2. Common faults and solutions

1. Magnetic force weakening or failure:

Cause of failure: magnet aging, damage, or unreasonable design of magnetic platen.

Solution: replace the new magnet or adjust the design of the magnetic platen to ensure that the magnetic force meets the requirements.

2. Looloose or off:

Cause of failure: unfafastened, material fatigue or improper installation.

Solution: tighten the connections with appropriate tools and replace the tired or damaged connections to ensure correct installation.

3. Surface corrosion or contamination:

Cause of failure: long-term exposure to wet, corrosive environment or not cleaning in time.

Solution: Clean the magnetic platen surface regularly to remove corrosion and stains. If the corrosion is severe, a repair or replacement is required.

4. Wear caused by poor lubrication:

Cause of failure: insufficient lubricant, improper selection, or delayed replacement.

Solution: select the right lubricant and add it regularly to ensure the smooth operation of the magnetic platen. Rebadly worn parts.

In short, through regular maintenance and maintenance, it can ensure the long-term stable operation of the injection molding machine magnetic platen. At the same time, the timely troubleshooting and solution of common faults and problems can also improve the service life and performance stability of the magnetic platen.

-----------------------------------------------------------------------------------

The development trend of magnetic force template in the injection molding machine industry

With the continuous prosperity of manufacturing industry and the rapid development of injection molding machine industry, magnetic platen as an important technology in the field of injection molding machine, its application is gradually deepening and showing a broad market prospect. This paper will discuss the development trend and future prospect of magnetic platen in the injection molding machine industry.

1. Technology upgrade and performance improvement

Magnetic enhancement and stability optimization: With the application of new materials and new processes, the magnetic performance of magnetic platen will be significantly improved, and the magnetic force is more powerful and stable, which can better meet the fixed requirements of large and heavy molds.

Structural design innovation: The structural design of magnetic platens will tend to be more compact and lightweight, while maintaining sufficient strength and stiffness. This will help to improve the overall performance of the injection molding machine and reduce the production costs.

2. Integration of intelligence and automation

Integration with the control system: In the future, the magnetic platen will be more closely integrated and integrated with the control system of the injection molding machine. Through data exchange and sharing, the magnetic platen can respond to the instructions of the control system in real time, and realize the automatic mold replacement and adjustment.

Intelligent management: With the help of the Internet of Things and cloud computing technology, the magnetic force template will realize intelligent management. Enterprises can remotely monitor the running status of magnetic platens, find and solve problems in time, and improve production efficiency and equipment reliability.

3. Environmental protection and sustainable development

Energy saving and emission reduction: the introduction of magnetic platen will reduce the energy consumption and emission of injection molding machine. Because the magnetic platen can achieve fast and safe mold replacement, reducing the downtime in the production process, thus improving the production efficiency and reducing the energy consumption. In addition, the magnetic platen also has lower noise and vibration, which is conducive to improve the production environment.

Green manufacturing: With the improvement of environmental protection awareness, green manufacturing has become an important development trend of manufacturing industry. As a green and environmental protection mold fixing device, magnetic platen will be favored by more enterprises. In the future, magnetic platens will pay more attention to the improvement of environmental performance, such as the use of environmentally friendly materials, optimization of production process.

4. Customization and personalized services

A. Customized demand: With the diversification of market demand, the customized demand of enterprises for injection molding machines is also getting higher and higher. As a kind of customizable mold fixing device, the magnetic platen will be able to carry out personalized design and manufacturing according to the actual needs of enterprises, to meet the special needs of enterprises.

B. Personalized service: In addition to product customization, enterprises also need personalized service support. In the future, magnetic platen suppliers will provide more comprehensive and professional services, such as technical consultation, installation and debugging, maintenance, etc., to ensure that enterprises can make full use of the advantages of magnetic platen to improve production efficiency.

To sum up, the development trend of magnetic platen in the injection molding machine industry will focus on technology upgrading, intelligent and automation integration, environmental protection and sustainable development, and customization and personalized services. With the continuous progress of technology and the continuous expansion of the market, the magnetic platen will play a more important role in the injection molding machine industry and promote the sustainable development of the manufacturing industry.

-----------------------------------------------------------------------------------

Article 7: injection molding machine magnetic force template case analysis

This paper will show the effect and value of the magnetic platen of injection molding machine in practical application through specific case analysis. The case will involve different industries, different models of injection molding machines and different types of molds.

Through the analysis and summary of these cases, we can have a deeper understanding of the application situation and the practical effect of the injection molding machine magnetic platen. At the same time, these cases can also provide reference and reference for other enterprises, and promote the wider application and development of magnetic platen technology.

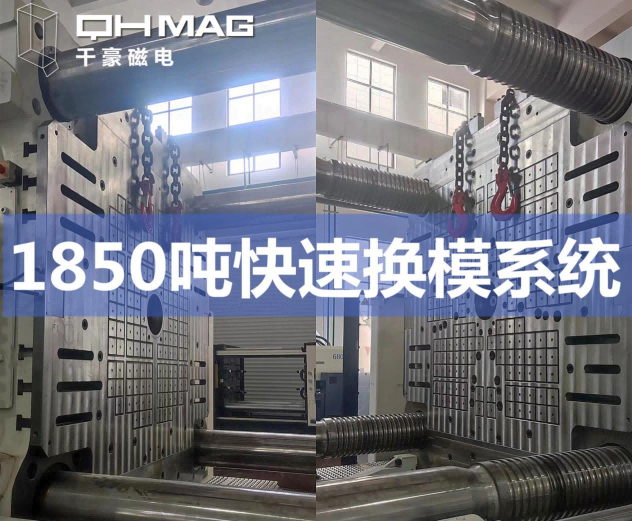

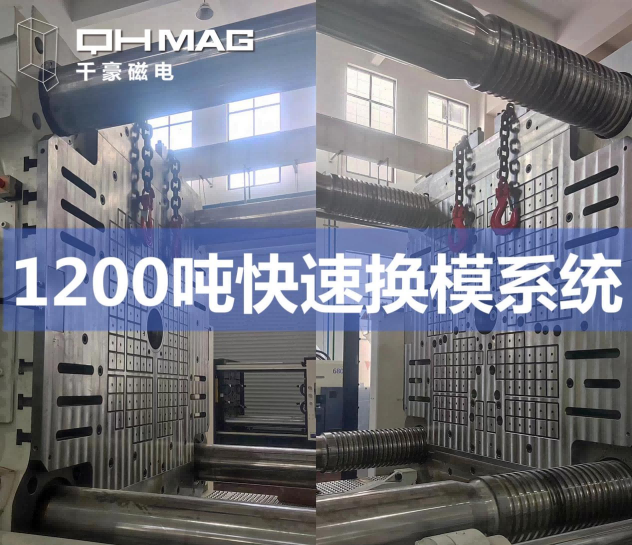

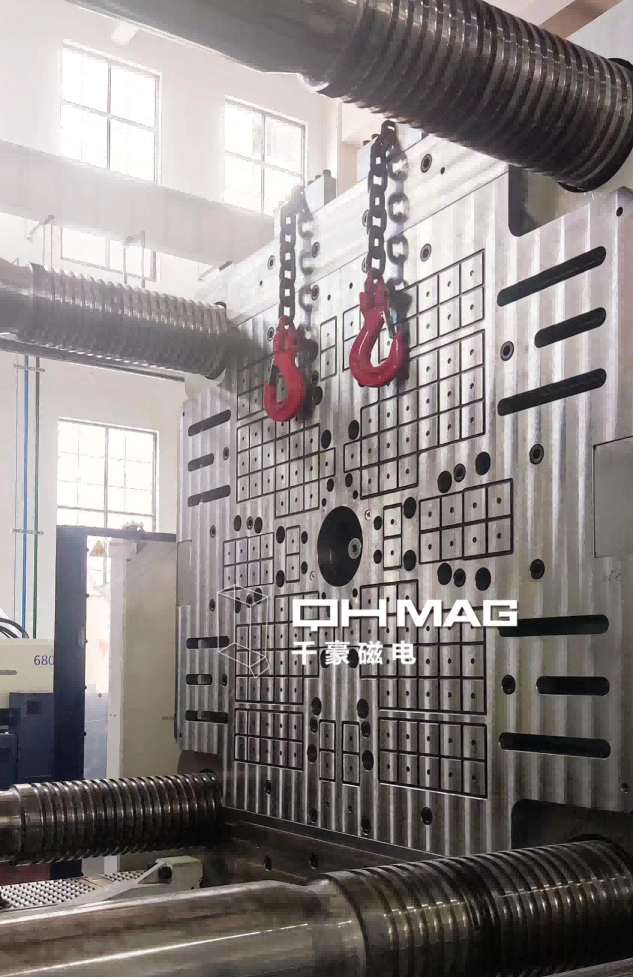

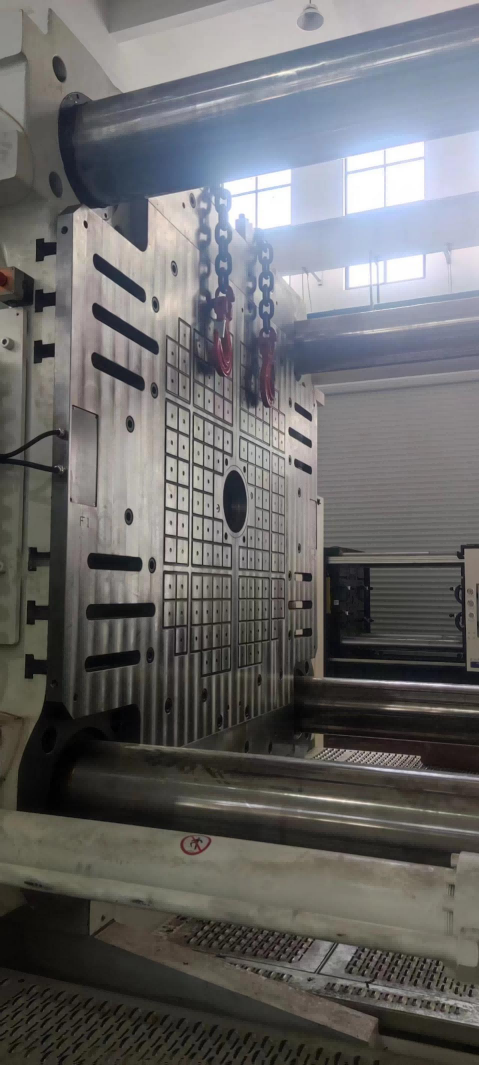

The following pictures are taken on the scene after installation.

Attn: Ian Yi

Mob: 8618974071177 (Wechat/ WhatsApp)

Email: [email protected]

Address: 101 room, 16 Building, LIANDO U VALLEY, No.36 Zhongke Road, Economic and Technological Development Zone, Yueyang City, Hunan Province, China