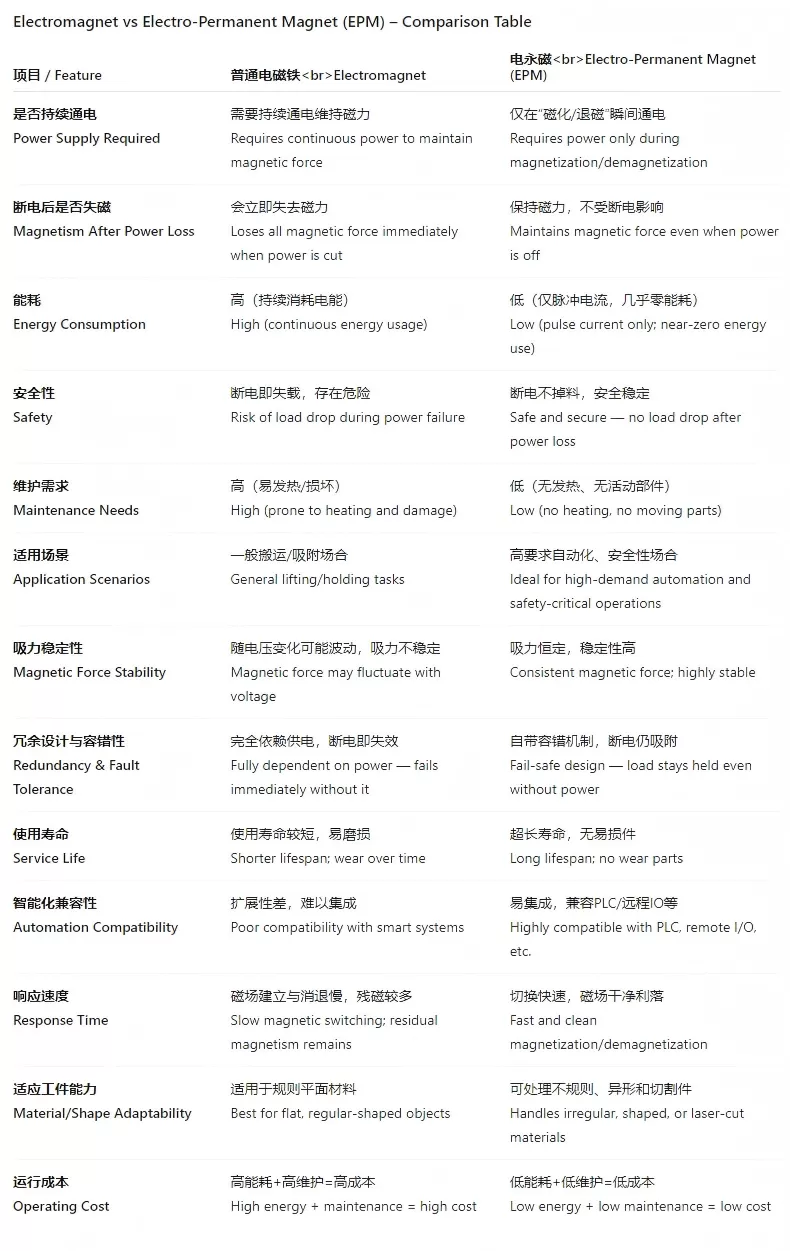

A quick comparison to help you choose the smarter lifting solution.

Electromagnet: Requires continuous power to maintain magnetic force

EPM: Requires power only during magnetization/demagnetization

Electromagnet: Risk of load drop during power failure

EPM: Maintains grip even during power loss — fail-safe design

Electromagnet: High (constant energy use)

EPM: Ultra-low (only pulse current needed)

Electromagnet: Prone to overheating and damage

EPM: No heat, no moving parts — minimal maintenance

Electromagnet: General-purpose lifting only

EPM: Ideal for steel plates, coils, pipes, and irregular laser-cut parts

Electromagnet: Magnetic force fluctuates with voltage

EPM: Consistent and stable force at all times

Electromagnet: High (due to energy + maintenance)

EPM: Low (energy-efficient and long-lasting)

Electromagnet: Limited integration capability

EPM: Easily integrates with PLCs, sensors, and smart systems

Attn: Ian Yi

Mob: 8618974071177 (Wechat/ WhatsApp)

Email: [email protected]

Address: 101 room, 16 Building, LIANDO U VALLEY, No.36 Zhongke Road, Economic and Technological Development Zone, Yueyang City, Hunan Province, China