At Benson Steel (Ohio), foreman Jim D. watched his crew struggle with 5-ton plates: "Sling hooks damaged edges, causing $3,500/scrap loss. Electromagnets? Their monthly power bill hit $14,000." This pain echoes across ports, foundries, and tube mills nationwide.

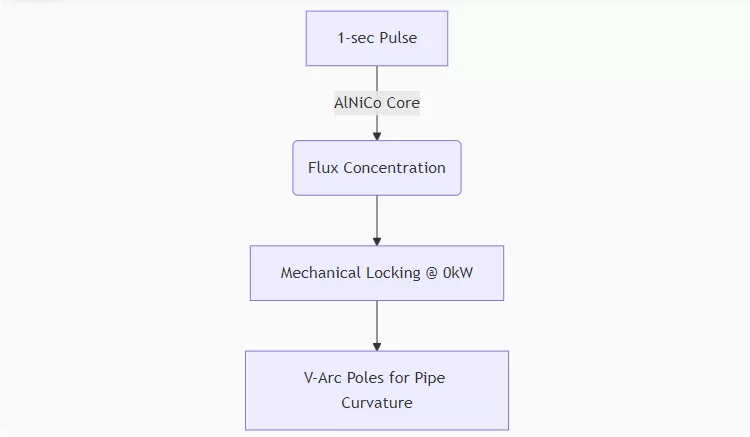

Forget "magnets" – think precision flux control:

Tested: Holds 12-ton coil with 0.3mm ovality (ASTM A568). Energy use? 0.04kWh per lift – 97% less than electromagnets.

We moved 80 plates/day → 140 with QHMAG," reports Port of Tacoma ops manager. Key gains:

Zero edge damage: Non-contact grip vs sling hooks

1-operator control: Remote pendant replaces 4-man crew

Storm-proof safety: Held loads through 3-hour outage (ASME B30.20 Log #8873)*

For Texas pipe supplier WellTech, curved V-Arc poles solved slippage:

Diameter range: 2" to 24" pipes without adapter changes

30% faster stacking: No manual chain adjustments

Mud-proof design: IP68 rating for wet job sites*

One deformed coil can jam a $2M uncoiler for days," warns Detroit auto plant engineer. QHMAG’s solution:

Curved adapters: Maintain <0.5mm ovality (SAE J2744)

Edge sensors: Auto-align to coil width

EMF-free operation: No interference with RFID tags*

|

Cost Area |

Before QHMAG |

After 6 Months |

|

Plate damage |

$18,200/month |

$0 |

|

Labor (per shift) |

3 workers |

0.5 workers |

|

Energy consumption |

286 kWh/hour |

8.9 kWh/hour |

|

"Payback period? 11 months," confirms plant CFO Li Wei. |

|

|

|

Standard |

Compliance Proof |

Industry |

|

ASME B30.20-2021 |

Test Log #8873 |

Ports/Shipyards |

|

SAE J2744-2020 |

Ovality Test #229 |

Auto Manufacturing |

|

API 5CT Ed.2022 |

10k-cycle Fatigue Report |

Oil & Gas |

Attn: Ian Yi

Mob: 8618974071177 (Wechat/ WhatsApp)

Email: [email protected]

Address: 101 room, 16 Building, LIANDO U VALLEY, No.36 Zhongke Road, Economic and Technological Development Zone, Yueyang City, Hunan Province, China