In the laser cutting industry, efficiency, precision, and safety are not just goals—they’re essential requirements.

Handling large steel sheets and hundreds of small, irregular parts after cutting remains a major challenge for most production facilities.

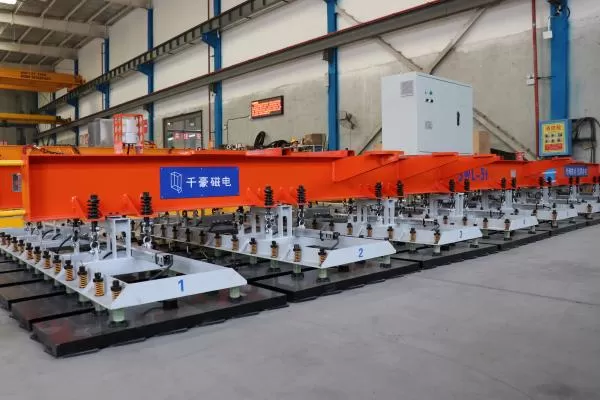

That’s where full-coverage electro-permanent magnetic lifters come into play.

Engineered by QHMAG, these systems provide a highly efficient and automated solution for both loading and unloading in laser cutting operations.Learn more about our electro-permanent lifting systems

Unlike vacuum or mechanical systems, QHMAG’s EPM lifters use magnetic force that remains active—even during power outages.

This guarantees safe, stable lifting of full-size steel sheets without deformation or slippage.

After laser cutting, the system automatically picks up all cut parts in a single cycle—completely eliminating the need for manual sorting.

This leads to dramatically reduced labor costs and increased throughput.

QHMAG’s full-coverage design features a matrix of magnetic modules that spans the entire surface of the steel plate.

This ensures uniform lifting pressure, preventing bending or damage—even when lifting thin or irregularly shaped materials.Discover how our smart factory solutions can optimize your workflow

The lifters are designed for low energy consumption, drawing power only during magnetization and demagnetization—making them ideal for manufacturers focused on cost control and sustainability.

For manufacturers using automated or lights-out laser cutting lines, QHMAG’s EPM lifters provide unmatched reliability.

They help eliminate production downtime, improve operator safety, and support lean manufacturing objectives.

QHMAG offers tailored magnetic lifting solutions for a wide range of sheet sizes, part geometries, and laser table layouts.

Whether you’re processing carbon steel, stainless steel, or aluminum, we can design a system to fit your workflow.

Explore our custom magnetic lifting options

If you're ready to automate material handling and increase profitability, now’s the time to switch.

Choose QHMAG full-coverage electro-permanent magnetic lifters—and elevate your productivity to the next level.

Contact our team today for expert guidance and a custom solution.

Attn: Ian Yi

Mob: 8618974071177 (Wechat/ WhatsApp)

Email: [email protected]

Address: 101 room, 16 Building, LIANDO U VALLEY, No.36 Zhongke Road, Economic and Technological Development Zone, Yueyang City, Hunan Province, China