|

Place of Origin: |

Yueyang City, Hunan Province, China |

|

Brand Name: |

QHMAG |

|

Model Number: |

QEPMZ84-106083 |

|

Certification: |

CE, ISO |

|

Material: |

Steel+NdFeb strong magnetic material |

|

Temperature: |

Default <100℃; Negotiable |

|

Characteristic |

Steel not fall down while the power-off suddenly |

|

Minimum Order Quantity: |

1 set |

|

Price: |

USD $2,000~ USD $20,000 |

|

Packaging Details: |

Wooden box packing, film packing |

|

Delivery Time: |

30 days |

|

Payment Terms: |

T/T, L/C, Negotiable |

|

Supply Ability: |

100 sets a month |

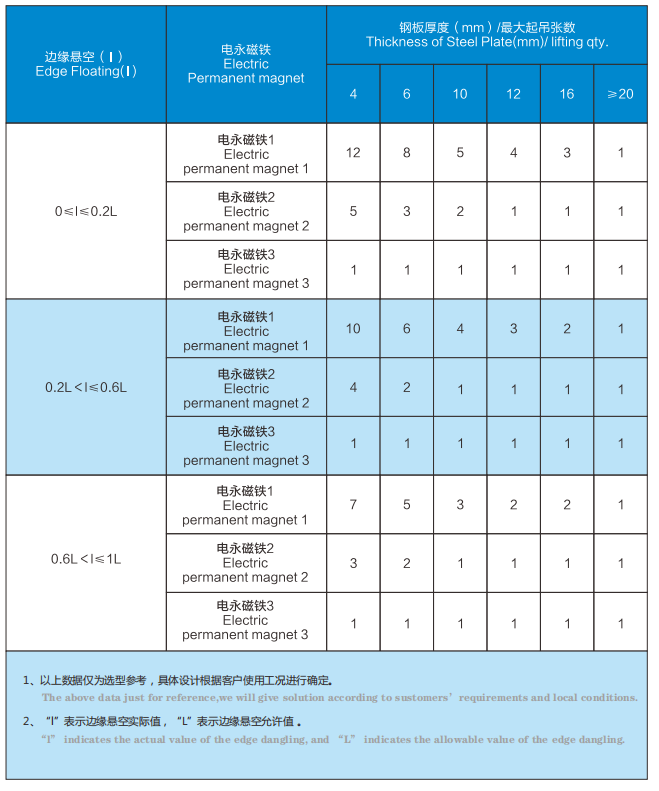

Electro permanent magnet technology is via electricity to control the magnetic field lines of the permanent magnet material, which expresses with magnetic force (magnetized state) or non-magnetic force(demagnetized state). it is an innovative application technology that can attract or release material independently

Magnetized state: Electro magnetic coil with instantaneous excitation current, which control the magnetic field state switching of reversible magnetic material, so that the magnetic field covering the surface of the magnetic poles and bring strong adsorption force. As the magnetic field form a closed loop,no magnetic loss, work with no heat, no noise, no energy consumption features.

Demagnetized state:in the magnetized state, the electromagnetic coil once again instantaneous excitation current, the built-in circuit to change the reversible magnetic field, so that the magnetic field converged inside the permanent magnet, and the magnetic pole surface no longer have magnetic field, the material is released.

Electric permanent magnet system only use electricity at the moment of magnetic charging and demagnetization, no need power during working process, no temperature rise, save electricity power more than 95% compared with electromagnet, big reduction of using-cost.

Both lifting permanent magnet and control system weights are light, can reduce the lifting equipment load improve lifting weight

The magnetism of Electro permanent lifting magnet is from 2 kinds of permanent magnetic material switch different natures. Maximum magnetic force is up to 16kgf/cm .No need electricity power during working, avoid the lifting magnet system magnetic power loss and the risk of sucked material falling down when power sudden failure or connection cable damaged. No attenuation even passed away longtime, with great security during using.

Electronic control operation only have charge, demagnetization buttons, easy to operate, only use 0.1-1s for magnetization and demagnetization, improved the operation efficiency. There is no wearing parts inside the permanent magnet system, no hydraulic oil compressed air etc.. no specific maintenance, only need to ensure that the surface clean, reliable and durable, no maintenance, and practical

After demagnetization, the surface, remaining magnetic force is almost 0 even if the small magnetic, particles will not adsorb on the surface of the magnetic pole, the absorptive will not scratch, will not cause remnants for the absorptive.

The internal of lifting permanent magnet adopt unique modular design,dual magnetic source technology, a unique product manufacture in a process,unique internal structure

The function of the control cabinet is complete, easy to control, support button control, long-distance control or remote control. Also with functions of dual magnetization cycle, magnetic switch, magnetization saturation detection safety buttons and other protection and detection functions.

Attn: Ian Yi

Mob: 8618974071177 (Wechat/ WhatsApp)

Email: [email protected]

Address: 101 room, 16 Building, LIANDO U VALLEY, No.36 Zhongke Road, Economic and Technological Development Zone, Yueyang City, Hunan Province, China