Our robots sat idle 15 hours/week fixing failed vacuum grippers," reports automation lead Sarah K. at a Detroit auto parts plant. Her pain reflects industry-wide data:

Vacuum pump failures: Cause 22% of robotic cell downtime (RIA 2023 Report)

Slippage incidents: Scrap $38,000/month in precision stamped parts

Changeover delays: 45 mins lost per product switch with manual retooling

Those noisy vacuum pumps sabotage efficiency:

✓ 15kW energy drain = $18,000/year in wasted power

✓ Seal replacements every 500 hours ($120/hour maintenance)

✓ Limited adaptability: Can’t handle porous/irregular surfaces

Fingers and clamps create new headaches:

Part distortion: 0.05mm deflection on thin gauges ruins weld alignment

Slow cycling: 2.3-second actuation time cuts throughput 15%

Safety risks: Pinch hazards require light curtains ($28k/cell)

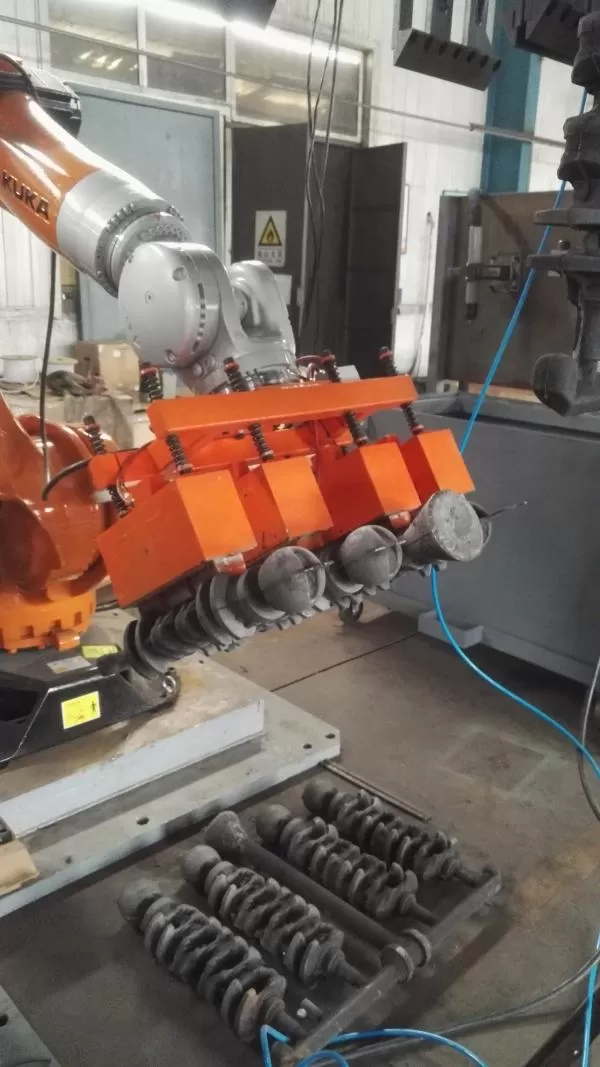

QHMAG breakthrough isn’t magic – it’s magnetic physics reengineered:

Instant activation: 0.3-sec magnetization cycles (10x faster than pneumatics)

Zero-distortion grip: 8,000 N/cm² hold without surface contact

Intelligent release: <0.5% residual magnetism (ANSI/RIA R15.08 certified)

Ford validation: 0.001mm part displacement during 2G acceleration

We achieved 99.98% grip reliability on porous cooling plates," states robotics engineer Carlos T. Results:

Downtime reduction: 18 hrs/week → 2 hrs/week

Energy savings: $15k/year vs vacuum systems

Safety upgrade: Eliminated pinch hazards

Challenge: Silicone valves slipping during robotic placement

Solution: QHMAG’s FDA-compliant non-marring gripper

Result: 0 particulate contamination in 500,000+ cycles

Calculate your savings:

Annual Savings = (Downtime hrs saved × $500/hr) + (Energy cost reduction) + (Maintenance cost eliminated)

Attn: Ian Yi

Mob: 8618974071177 (Wechat/ WhatsApp)

Email: [email protected]

Address: 101 room, 16 Building, LIANDO U VALLEY, No.36 Zhongke Road, Economic and Technological Development Zone, Yueyang City, Hunan Province, China